A Comprehensive Overview of Paper Bag Making Machines

The demand for eco-friendly alternatives to plastic bags has fueled the growth of the paper bag industry. Central to this industry are paper bag making machines, which enable efficient and effective production of various types of paper bags. This article aims to provide a detailed exploration of the different types of paper bag making machines available in the market, highlighting their functionalities and advantages.

I. Sharp Bottom (V Bottom) Paper Bag Machine:

The sharp bottom paper bag machine specializes in manufacturing bags with a distinct V-shaped bottom. Operating by feeding a roll of paper, the machine undergoes printing, gluing, and folding processes. Key features include precise folding mechanisms and compatibility with different paper thicknesses. This machine finds extensive application in the food and retail sectors.

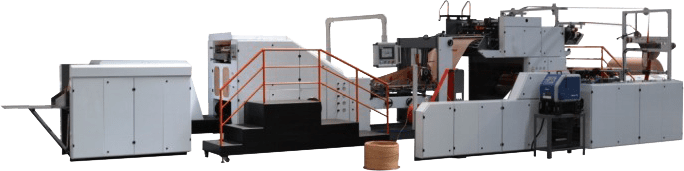

II. Auto Roll Fed Square Bottom Paper Bag Machine with Twisted Handle:

Designed specifically for auto roll fed square bottom paper bag machine with twisted handles, this machine excels at automatically feeding paper rolls. The paper goes through printing, gluing, and folding, with the twisted handle integrated during the manufacturing process. These bags are sought after for shopping and gifting purposes, providing durability and an appealing packaging solution.

III. Automatic Square Bottom Paper Bag Machine with Flat Handle Overfolded or Upright:

Capable of producing automatic square bottom paper bag machine with either overfolded or upright flat handles, this automatic machine operates by feeding a paper roll. Printing, gluing, and folding processes shape the bag, while the flat handle is added accordingly. These bags are widely utilized in grocery stores, boutiques, and takeaway food establishments.

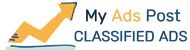

IV. Roll Fed Square Bottom Paper Bag Machine:

Ideal for high-volume production, the roll fed square bottom paper bag machine continuously feeds paper rolls to create square-bottom bags. Printing, gluing, and folding processes shape the bags, which are then cut and separated. This machine excels in industries such as retail, food, and packaging, offering rapid production capabilities.

V. Automatic Square Bottom Paper Bag Machine with Twisted Rope & Flat Handle:

Combining versatility and functionality, this automatic square bottom paper bag machine with both twisted rope and flat handles. It operates by feeding a paper roll, undergoing printing, gluing, and folding processes. The twisted rope and flat handles are integrated during bag production, making these bags suitable for fashion, luxury goods, and promotional events.

VI. Semi Automatic Sheet-fed Square Bottom Paper Bag Machine:

The semi-automatic sheet-fed square bottom paper bag machine requires manual feeding of individual paper sheets. While suitable for lower production volumes, it offers flexibility in terms of paper size and bag design. Although it involves more manual intervention, this cost-effective option is ideal for small to medium-scale bag manufacturing businesses.

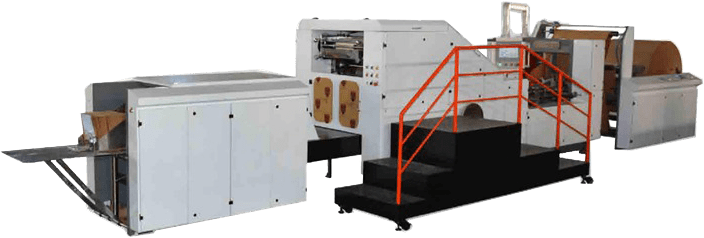

VII. Fully Automatic Sheet-fed Square Bottom Paper Bag Machine:

At the forefront of automation, the fully automatic sheet-fed square bottom paper bag machine enables efficient and high-speed bag production. It handles various paper sizes and thicknesses, incorporating printing, gluing, and folding mechanisms. This machine is favored by large-scale bag manufacturing operations, ensuring consistent quality and productivity.

Conclusion:

Paper bag making machines play a vital role in meeting the increasing demand for sustainable packaging solutions. By understanding the functionalities and benefits of different types of machines, manufacturers can choose the most suitable option for their specific production requirements. Whether it’s creating bags with unique bottom shapes, incorporating various handle types, or accommodating different production volumes, the diverse range of paper bag making machines caters to the varied needs of the industry. With these machines, the transition to eco-friendly paper bags becomes more accessible and efficient, promoting a greener future.