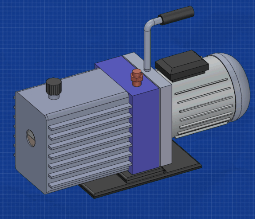

Case studies: Successful applications of Vacuum Pumps in different industries

Vacuum pumps are an essential component in many manufacturing processes and industries. Over the years, their application has proven to be both efficient and cost-effective. In this article, we’ll discuss some successful case studies of vacuum pump applications across various industries.

Chemical Industry – Vacuum pumps are most commonly used in the production of chemicals because they provide high-vacuum levels required for chemical process reactions. Without the right level of vacuum, these valuable chemical compounds could be lost due to gaseous diffusion or vaporization. As a result, they serve as an indispensable component of any chemical process lines.

Electronics Industry – Vacuum pumps provide the right level of vacuum pressure to assist with different electronics applications such as degassing liquids and curing coatings on PCBs (printed circuit boards). They also help with fabricating printed circuit boards by extracting air-borne debris particles before applying solder paste deposition and etching processes to further increase yield rates and product quality.

Food & Beverage Industry – Food products need to be stored in a hermetically sealed container or package, which requires low gas partial pressure to impart safety against spoilage due to contaminants or pathogens in the atmosphere. Vacuum pumps allow one to reach lower levels of gas partial pressure and thus ensure maximum safety for food products.

Automotive Industry – Automotive production lines require high levels of suction force or vacuum power when painting parts or assembling components that may contain air within them. By using proper vacuum pumps, workers can extract all lingering air from surfaces which helps ensure smoother end products with better adherence properties as well as less wastage due to uneven paint builds or poor assembly fitment when parts seal together too loosely.

Medical Industry – Vacuum pumps have wide value propositions within medical settings too due to their ability to create low gas concentrations inside confined spaces like syringes, test tubes, pipette tips, and other small containers used in laboratories around the world. Thus they play an important role when it comes to analytical testing processes involving airless containers filled with certain specimens or reagents.

Conclusion – We’ve discussed four diverse industrial sectors above that make use of vacuum pumps during their operations but there are countless more out there including the aerospace and aviation engineering industry too where operators run highly sophisticated tools that rely on real-time data metrics collected through well-managed vacuums under ideal atmospheric conditions at all times within fuel tanks etc. Overall it is clear that employing these specialized pieces of equipment not only increases efficiency but often provides economic soundness too since their overall price points tend to stay pretty steady over long periods compared with other instruments belonging in similar fields.