Strainer supplier in UAE

GLOBE VALVE SUPPLIER SAUDI ARABIA

Middleeast valve are top rated Globe valve supplier Saudi Arabia. It supplies industrial valves in Bahrain, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar & Saudi Arabia. Globe valve is a kind of a valve that is used to control flow in a pipeline, and it has a spherical body with a moving plug or disc element and a stationery ring seat. Globe valves have a very good throttling ability. It is used for flow regulation. These valves can have a manual or automatic operation. It is a valve primarily designed to stop, start, and regulate flow.

Generally, the globe valve body material is an option of brass/bronze in low pressure applications and forged carbon steel or stainless steel for higher pressures and temperature.

Different types of Globe Valve:

- Pressure Seal Globe Valve

- Bellow Seal Globe Valve

- Y Type Globe Valve

- Angle Type Globe Valve

- Forged Steel Globe Valve

Different industries in which globe valve is used in:

- Fuel oil systems.

- Feedwater or chemical feed systems.

- Boiler and main steam vents and drains.

- Turbine lube oil system

Valves from Middleeast valve are the answer to all your industrial requirements in Oman, Qatar, Saudi Arabia, United Arab Emirates and Kuwait. We offer cost effective valves without compromising quality. We devote more time and resources to our Globe valves to ensure that they can withstand extreme conditions.

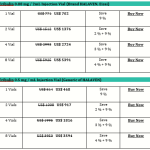

Description:

Body material: Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class: 150 – 2500

Nominal pressure: PN10 – PN 450

Size: DN 10 – DN 1200

Ends: Butt weld, Flanged, threaded, socket weld

Operations-: Hand-wheel operated Globe Valve, Pneumatic actuated Globe Valve, Electric actuated Globe Valve, Gear operated Globe Valve

https://www.middleeastvalve.com/product-category/globe-valve/

Middleeast valve is one of the reputed Strainer supplier in UAE. It supplies industrial valves in Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, the United Arab Emirates, and Yemen. Your needs for valves can be met by our qualified team. Our valves are made from premium materials in our advanced or innovative manufacturing facility.

A pipe strainer is a mechanical device that is used to remove solids from a fluid flow. This is accomplished using a straining element made of perforated metal, mesh, or wedge wire. The typical range for strainer particle holding is 1′′ to 40 microns (0.0016′′).

Strainers are used in pipelines to protect downstream machineries like condensers, cooling systems, pumps, compressors, meters, spray nozzles, generators, and steam traps from the damaging effects of sediments, corrosion, pipe scales, and other foreign debris.

Types of Industrial strainers:

Y-Type strainer- They are named as Y type strainers because of their shape. Y Type Strainers are commonly used for coarse filtration or pre-filtration. However, because it has a large filtration area, it can also be used with fine mesh. The Strainer increases medium clearance and extends valve life; it also protects expensive pumps, meters, and other mechanical devices. It is ideal for liquids such as water, air, coal, petroleum, steam, and others.

The Y-Strainer can be installed in either a vertical or horizontal orientation, with the filtration element pointing downwards, allowing material to be collected at the strainer mesh’s lowest point. It also has a blow-off connection for easy cleaning.

Advantages of Y- Type Strainer:

- Superior flushing capabilities due to built-in blow-down ports

- Better return on investment.

- Provides greater overall flexibility

- Larger open ration area compared to T type

Basket Strainer- Basket strainers can strain and filter a wide range of fluids and hold solid components of almost any size. They are all retraceable and easy-to-clean baskets. Basket strainer components can be delivered in single cylinder, double cylinder, multi-cylinder, and pleated styles, depending on the application specification. They have a filter housing, a perforated cage-supported filter element, a positive sealing arrangement to prevent bypass, and several end link options.

Advantages of Basket strainer:

- Available in duplex and simplex configurations.

- Can be serviced without disrupting flow.

- Suitable for continuous flow pipeline applications.

- The maximum operating temperature is 220°.

- Carbon steel, stainless steel, and cast iron are among the materials available.

T-Type Strainer- Tee strainers are custom-made compound strainers used to remove foreign contaminants from pipelines. Tee Style Strainers are a low-cost option for straining specifications with a high nominal bore. They are designed for right-angled installations and can be installed in vertical or horizontal pipes.

Advantages of T- Type Strainer:

- It has covers that open quickly.

- Additional vent ports and differential pressure taps are available. Flow capacity is increased despite smaller open ratio areas due to a straighter flow path.

- When installed horizontally, chamber covers can be opened without allowing process fluid to drain out, which is advantageous in more hazardous processes.

- Superior for transferring fluids at high speeds.

- Ideal for larger pipeline applications that require immediate access to the strain.

Simplex and duplex basket strainer

Application of strainer:

- In Upstream of valves, compressors, and pumps, industrial strainers are frequently used. These are sensitive devices that increase the complexity and effectiveness of the piping system. Industrial strainers are also useful when the medium is heavier or contains chemicals that must be removed.

Industries in which strainer is used:

- Chemical Industry.

- Water treatment Industry.

- Petroleum Industry.

- Marine Industry

- Power generation

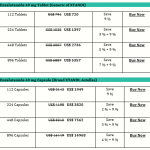

Description:

Material: Bronze, Cast Iron , Cast Carbon Steel, Cast Stainless Steel, Stainless Steel (SS202, SS304, SS316), Forged Brass Body, Ductile Iron, PP, Forged Stainless Steel (F304, F316), Forged Alloy Steel Body.

Pressure rating: PN6-PN450

Class- 150-2500

End connection: Flanged, Butt weld, threaded, socket weld.

Size: ¼ Inch to 24 Inch